At LEMMA, we believe that the best way to get a trustworthy numerical solution to a challenging industrial problem is to properly handle three key aspects of the simulation process – namely the mesh, the physics, and the numerics.

First, industrial designs often exhibit stringent geometrical features (complex blueprints, moving parts) that are difficult to properly reproduce without an adequate meshing technology.

Second, industrial flows involve a combination of physical phenomena related to a wide spectrum of domains (multi-phase flow, turbulence, structural mechanics, heat transfer…) which need to be properly modelled.

Finally, the numerical methods need to be robust enough to dampen the numerical instabilities and, at the same time, be precise enough to capture the physical ones.

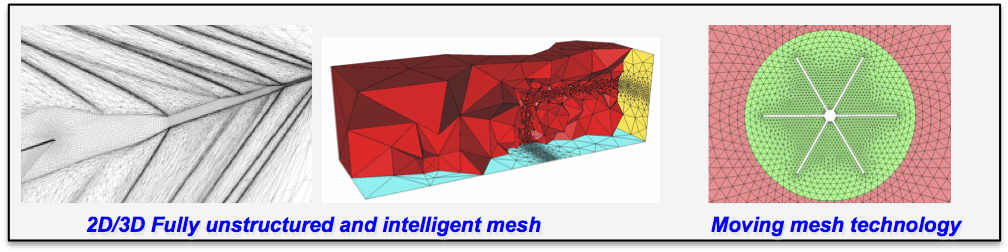

Meshing technology

- The intelligent mesh is a powerful tool to reduce the cost of numerical simulations while preserving a desired level of accuracy. The main idea is that, at fixed number of vertices, all meshes are not equivalent in terms of numerical efficiency. Indeed, some meshes will lead to smaller numerical errors than others.

- Contrary to most of the currently available adaptation technologies, our mesh adaptation process is not based on a simple refinement coarsening strategy depending on a purely local error estimation. Our strategy controls local as well as global numerical errors. Moreover, it does not only adapt the mesh in terms of number of vertices but also in terms of elements shape and orientation. This method leads to meshes which can exhibit very stretched elements, generally in accordance with the physical phenomena at stake.

- The intelligent mesh method has been successfully applied to a wide range of flows such as:

– the sloshing in ship and aerospace tanks under gravity or in micro-gravity

– the three-phase separation in a FPSO tank

– sea-keeping problems combined with the numerical basin

– splashing of a breaking dam (Guegan et al. Int. J. Num. Meth. Eng. 2010)

– compressible two-phase flows

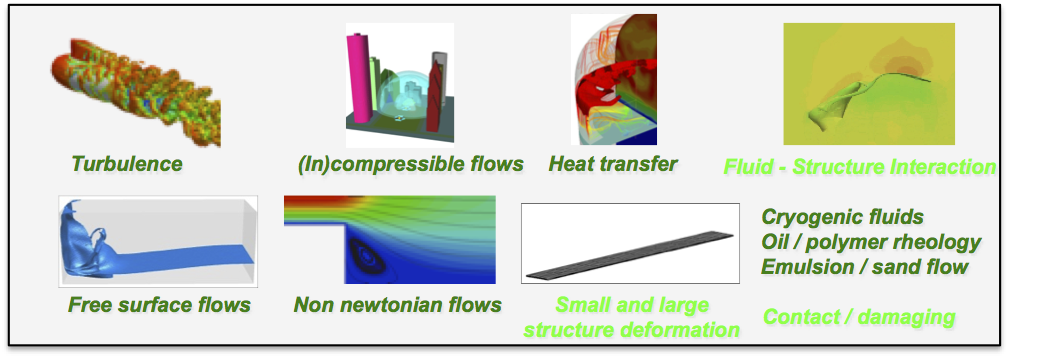

Modelling technology

- Thanks to the contributions of experts in applied mathematics, fluid and structural mechanics, we were able to build our software around cutting-edge methods optimised for parallel computing. Now, we can deliver accurate solutions to challenges in a wide variety of fields, thanks to our integrated multi-physics software NICEFLOW®. See below for a brief overview of the modeling capabilities of our software.

Numerical technology

What are the common points between the tridimensional multi-phase flow in a kilometric pipe, the sea-keeping of a full scale boat during three hours, the shock pattern kilometers around a supersonic fighter jet and the dynamics of wing tip vortices several kilometers behind a business aircraft ?

- All these full-scale problems involve a wide range of dimensions that cannot be properly captured using traditional numerical approaches without a prohibitive CPU cost.

- Yet, all these problems have been solved with NICEFLOW®.

By combining cutting-edge technologies to cope with these three aspects in its fully integrated NICEFLOW® solver, LEMMA will provide the best solution possible to your numerical challenges. As a matter of fact, LEMMA is able to bridge the industry, research and academics world to bring to the market a unique offer of models and methods.